singlespeed

Well-known member

True. But a round peg in a square hole never looks at home.waitey":opybsif2 said:I somewhat liked the large single tip as it just screamed "this bitch isn't standard!"

True. But a round peg in a square hole never looks at home.waitey":opybsif2 said:I somewhat liked the large single tip as it just screamed "this bitch isn't standard!"

Dubz":23bni6nh said:Looks much better with a twin tip!

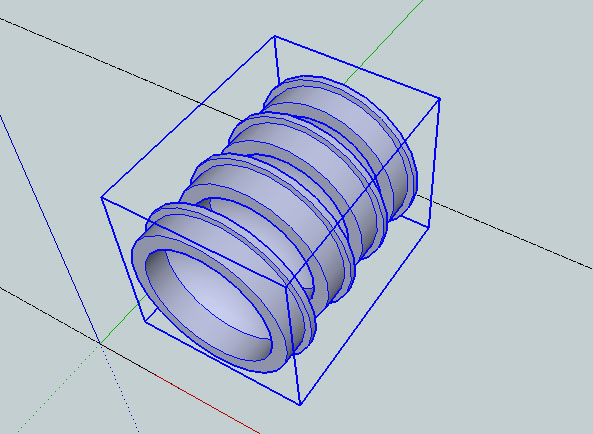

Waitey the noise this thing will make when it's finish ( or this stage of modding) will scream "this bitch ain't standard"

Its already got its own post >>on this page<<markhardy":5px9t0yt said:Neil I think we need a thread dedicated to your mud flaps as it has been asked so many times in this project thread (I'm guilty of asking myself) :lol:

Could do.Friedchicken91":2cdfdwwf said:Neil you know you love me right? Fancy getting one of those tips made for me?